Happy Birthday No. 1702!

On September 9th, 2017, the Great Smoky Mountains Railroad celebrated the 75th Birthday of our steam locomotive No. 1702. The specialty excursion ran between Dillsboro and Bryson City, North Carolina, featuring photo runbys at select locations. In Bryson City, the passengers enjoyed a turntable demonstration, a ninety-minute layover, and a celebratory birthday cake. After lunch, 1702 performed multiple runbys on the trip back to Dillsboro, including a stop at the famous wreck scene from the film “The Fugitive!” Sporting special white “Extra” flags, 1702 performed twelve runbys for the passengers over the course of the day, a new GSMR record!

This excursion was the first time No. 1702 completed a trip facing both directions without the assistance of diesels. We thank the passengers who chose to ride this historic excursion, your support assures that special excursions are possible in the future.

If you did attend the 75th Birthday Celebration of No. 1702, send in your best photo and be entered to win a FREE steam cab ride on a regular excursion of your choosing. To submit your entry, visit our submission form located HERE.

To view the remainder of the 2017 steam schedule, visit our website, located HERE.

Thank you to Smoky Mountain Steam for the use of these video clips, more videos are available on their YouTube channel located HERE. Make sure to watch in High Definition!

The train crew who made this historic run possible, kudos fellas!

The train crew who made this historic run possible, kudos fellas!

Share Your Memories!

The Great Smoky Mountains Railroad invites you to share your memories with us! In honor of 1702’s 75th Birthday, GSMR will be creating a “memory board” spotlighting the Steam of the Smokies! We want you to submit your favorite photos and videos of #1702 from any era! When doing so, you will have a chance to see your memories shared on GSMR’s official social media accounts and various other platforms. We are searching for vintage photos from all points in 1702’s history. You may even see your photo featured on our website!

The Great Smoky Mountains Railroad invites you to share your memories with us! In honor of 1702’s 75th Birthday, GSMR will be creating a “memory board” spotlighting the Steam of the Smokies! We want you to submit your favorite photos and videos of #1702 from any era! When doing so, you will have a chance to see your memories shared on GSMR’s official social media accounts and various other platforms. We are searching for vintage photos from all points in 1702’s history. You may even see your photo featured on our website!

The link to the Memory Board submission form is located HERE

Here is a throwback from an Andrews excursion in 2004!

We can’t wait to see what you have to share!

Trains and Totality!

A once in a lifetime opportunity to witness a total solar eclipse – what an experience!

The Great Smoky Mountains Railroad hosted a Solar Eclipse Train on August 21, 2017. With over 600 passengers aboard and a passenger train that extended more than 12 cars, 2 diesel engines, and 1 steam locomotive, this specialty train made tracks to Dillsboro for a two-hour layover and high expectations for a great show from nature.

While in Dillsboro passengers were able to enjoy live music, shopping, restaurants, and various food vendors. The highlight of the excursion was the one minute and fifty-seconds of 100% totality; whistle blasts from 1702 were used to signal the beginning and end of totality.

During this rare event our town alone received over 60,000 guests in under 3 days! GSMR staff and both diesel and steam crews did a fantastic job keeping our locomotives running and our trains on time. A day we will never forget!

This year is turning out to be very special for 1702, stay tuned for more announcements coming soon!

To view 1702’s operating schedule click HERE.

A Home Away From Home

Steam locomotives like 1702 require constant maintenance and care during their regular operation, this gives little to no time to make the sixteen-mile run back to our steam shop for servicing. To help assure that 1702 is properly cared for, a new steam shed has been constructed next to the turntable in Bryson City. The steam shed will allow for the locomotive to be stored under cover while being serviced and awaiting future excursions. Construction was led by Tom Falicon, the shed measures seventy-five feet in length, forty feet wide, and nearly thirty feet tall. 1702 will be on display each evening following the day’s steam excursions.

To view 1702’s 2017 calendar, click: HERE

It’s Boiler Wash Time!

We have many people ask what happens when 1702 is not operating, here is your answer!

An important step each month in the caring for a steam locomotive is a boiler wash. Having a regularly scheduled boiler wash ensures that a locomotive boiler is free from all corrosion and scaling, which if left uncleaned could over time deteriorate the boiler and lead to damage.

The first steps in a boiler wash are emptying the boiler and removing the brass washout plugs. High-pressure water is then sprayed through special tools to clean the interior of the boiler and smokebox. It is not a clean job, but our steam guys love taking care of 1702.

A new tool box was added to the front of the tender last week, this will help with in-cab-maintenance/repairs while the locomotive is in motion. 1702 is scheduled to run the Tuckasegee River Excursion on July 6th, come take a ride or stop by and say hello!

Check out the steam schedule by clicking HERE!

And………We’re BACK!

Hello 2017!!! 1702 is already having a busy year as we begin prepping for its 75th Birthday! To start us off we will begin with a brief overview of our winter maintenance.

After finishing the 2016 operating season, 1702 underwent a federally mandated annual inspection, the first annual inspection for the locomotive since it returned to operation. After a successful inspection, the locomotive was given new spring rigging for the driving wheels, cylinder packing, air pump lines and piston rings.

Other work was also completed on the tender brake rigging, steam turret, and headlight. Smaller projects such as stripping and polishing the brass number boards, painting the upper porthole cab windows and bell interior, and creating a new whistle lever handle, were also completed.

A big project for the steam shop over the winter was constructing a cross compound Westinghouse air compressor, which was composed of miscellaneous parts. With all of this complete, 1702 was ready for her debut at the 2017 Association of Tourist Railways & Railroad Museums known as HeritageRail Alliance Conference, on April 27-29. More to come about this successful conference in our next blog!

The engineer’s side of the cab on No. 1702

The Fireman’s side of the cab on No. 1702

The new Westinghouse cross-compound steam air compressor

New lines on the air pump.

The new cosmetic details on No. 1702, Brass number boards, red porthole windows, and a cherry red bell interior.

#1702 Official Celebration

Since the re-debut of #1702 we have made sure to take time and celebrate the return of this historical steam engine not only with our employees but our community as well. Because of the unique nature of GSMR’s public/private partnership with Swain County we indeed have a lot of fantastic supporters to celebrate with.

Friday, Aug 5, GSMR celebrated the official debut of #1702 with a specialty ceremony and evening reception train. Our guests along with employees enjoyed a train ride with #1702 leading the way to the Fontana Trestle and back while dining on a fantastic spread of food prepared by our excellent Food and Beverage Staff.

The evening began with a special ceremony in which our owners Al & Carol Harper recognized all the hard work and dedication of the steam engine restoration crew, turntable crew, and Swain County community leaders. Specialty plaques that will be placed inside the cab of #1702 and at the turntable were also unveiled. We made sure to grab some photos to share!

See below, our restoration crew paused for a photo op with some of the Harper Family, GSMR General Manager and GSMR Superintendent of Operations.

(Left to Right) John Campasino, Robert Franzen (Steam Services of America), Brian Brooks, Kim Albritton, Marshal Harris, Joe Stewart, Al Harper, Carol Harper, and John Harper.

More of The Harper Family enjoying #1702!

Mr. Harper cut the ribbon and officially christened #1702!

The Steam of the Smokies has Returned!

What a whirlwind last few months that we have had! So many parts have finally been placed together, welded, installed, or finished that it’s hard to recap!

What we can finally celebrate is that #1702 is operational again, and that is a huge triumph for the restoration project.

Our crew; Joe, Brian, and Marshal along with Robert Franzen of Steam Services of America have been in overdrive the past few months to make sure that we would fall as close to our debut date of July 22 as we could.

On July 21, #1702 took her first steps in the Dillsboro railyard 100% independently operational. After that successful mini trial it was decided that a test run would be performed the next morning from Dillsboro to Bryson City.

About half way through the morning test run a mechanical issue with the wheel bearing overheating was discovered. This caused #1702 to be stopped immediately for repairs on the main line. Once stopped the crew removed the cellar box on the rear #4 driver and found that the brass bearing and axle was being damaged due to the lack of lubrication causing the bearing to heat up. Unfortunately the engine had to be returned to the shop in Dillsboro for further repairs upon this discovery. Fortunately, the damage to the brass bearing and axle was not that significant because the issue was found quickly by the GSMR Crew and Robert Franzen of Steam Services of America on the initial test run and the #4 driver did not have to be dropped out.

The engine remained in Dillsboro for the next 48 hours, with the assistance from Steam Services of America our crew focused on the repair of the bearing and lubrication problems. While it was out for service they also inspected the oil lubrication system that provides oil to all bearing boxes to prevent future overheating problems. Other minor improvements included modifying the burner and adding a new fuel flow valve to improve the firing process.

On Sunday July 24, another test run was completed successfully arriving to Bryson City with cheers and applause from spectators.

Tuesday July 26, the engine set out for its first successful passenger excursion on the Tuckasegee River run. Along the route rail fans waited at every crossing to take the opportunity to capture #1702 on her first journey. We have seen some great photos on the web, thanks to all who shared.

After completing two successful Tuckasegee River Excursion trips, the crew prepared for the first Nantahala Gorge Excursion on Friday July 29. For its’ first run to the Gorge the train was sold out, full of excited passengers and fans. Everyone enjoyed finally hearing the sound of the steam engine and the whistle echoing between the beautiful scenery of the Smoky Mountains!

Saturday evening a problem with the throttle opening and closing properly left the engine powerless. #1702 had to be taken back down to the steam shop in Dillsboro for a proper shut down and repair. Once shut down the crew inspected the throttle thoroughly and found that they could repair it by machining new parts to correct the operating malfunction. In order for the engine to have enough time to be fired up and ready to operate on Wednesday Aug 3, the Tuesday trip had to be changed to Diesel only.

We appreciate all of the fans who have followed this journey and continue to stay passionate about this important restoration work. With such a historical piece of equipment we are looking forward to the continued work that it will require to stay in top shape! We hope to see you riding steam in 2016!

Turntable Update

Just a quick update from our Project Manager, Tom Falicon on the turntable in Bryson City!

Ties have been installed on the deck of the turntable bridge. The longer ties support walkways so the crews can walk past the engine while it is on the turntable.

Short ties have been cut and are being installed under the turntables ring rail.

A storm water control manhole assembly was installed in order to create a central location for all storm water to be pumped out to a newly excavated retention pond.

18 cu. yards of concrete was poured into a pit to create a solid base for our locomotive inspection pit to rest on.

This month both the precast concrete inspection pit and the precast concrete bridge for the rail passing over the nearby creek will be installed.

The Pressure’s On!

Our last blog post featured a few videos of the flue tube instillation and we are happy to report that the boiler is ready for water and pressure (hydro static testing)! A huge step in our final months of completion before our scheduled return of #1702 this summer!

Since the completion the guys have been using compressed (120lbs per square inch) air to test the pressure inside the boiler. Steam Services of America contractor Bob, explained that by using soap and water they can easily locate where the leaks are allowing the air to escape, causing suds to appear. Once identified the leaks will be sealed. The next step is the hydro test which should be conducted sometime this week. After the test is completed a few minor additional items that the boiler needs can be installed and the boiler can be prepped for initial fire-up testing.

Last week Brian worked to complete the fabrication of the water column that will gauge the water level in the boiler.

The engine was moved so that they could prepare to reposition the tender behind the engine. While preforming the first movement test they discovered a few needed repairs to the entrance track of the steam shop. Those will be repaired before the next move.

While #1702 was outside the guys enjoyed giving it a much needed wash!

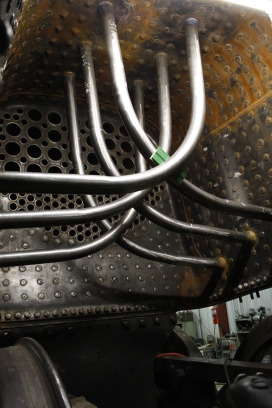

You can certainly see a change in the firebox interior with the instillation of the tubes and flues and now the transverse arch tubes. These transverse arch tubes are the newest addition. Originally arch tubes were inside the firebox but this new transverse design will prove to be more efficient in circulating the water from the side sheets to the top crown sheet allowing the water to be heated faster and more efficiently.

You can certainly see a change in the firebox interior with the instillation of the tubes and flues and now the transverse arch tubes. These transverse arch tubes are the newest addition. Originally arch tubes were inside the firebox but this new transverse design will prove to be more efficient in circulating the water from the side sheets to the top crown sheet allowing the water to be heated faster and more efficiently.

Steam Services of America also delivered the 30 New Sets Super Heater Units in March. The SH Units will be installed once the hydrostatic testing of the boiler is finished and the boiler is being prepped for fire-up. The SH Units which are installed in the smoke box and lay inside the flues inside the barrel of the boiler take the saturated steam generated in the boiler and reheat the steam through the SH Unit piping from the gases from the firebox which travel trough the super heater flues heating the steam inside the SH Units. The saturated steam is about 450 degrees Fahrenheit when taken out of the boiler and heated to approximately 650 degrees Fahrenheit after passing through the SH Units. Once the steam is superheated it then enters into the valves and pistons where the steam goes to work moving the engine drive wheels.

Our anticipation is growing with the excitement of finally seeing #1702 back on the line! We hope that you have booked your ticket. If not, find all the information HERE.